BENEFIT OF CQI MANUFACTURING INDUSTRIES

Has its roots in an OESA document The Suppliers Practical Guide to Warranty Reduction published in November 2005. Companies that actively look for ways to enhance their business will invariably increase the value of their products and services.

The Importance Of Continuous Quality Improvement Thrive Efficiency Realized

Continuous improvement benefits from the time and space to grow such as by starting with low-risk projects as vehicles to engage and train staff.

. Efforts to improve the quality safety and efficiency of health care provision have often focused on changing approaches to the way services are organized and delivered. This study shows that it is cost-beneficial for local manufacturing companies to invest in quality improvement interventions. The principle underpinning quality improvement was that quality was not something controlled at the end of the line but rather throughout the entire work process.

Continuous Quality Improvement 9-5 Boost service delivery and help maintain consistently high quality. This will lead to more sophisticated and overall more economically competitive offerings. Focus on key processes and process steps identified as requiring special attention from multiple levels of plant personnel to ensure compliance due.

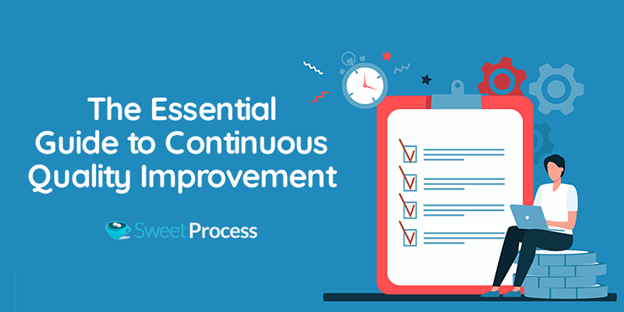

The Shewhart Cycle also known as the Delming Cycle or PDCA which stands for Plan-Do-Check-Act or an approach called Kaizen are the two most well-known frameworks. A Guideline for Industry Best Practices. 13 HOW CAN CQI HELP A PRACTICE MAKE THE MOST OF MEANINGFUL USE.

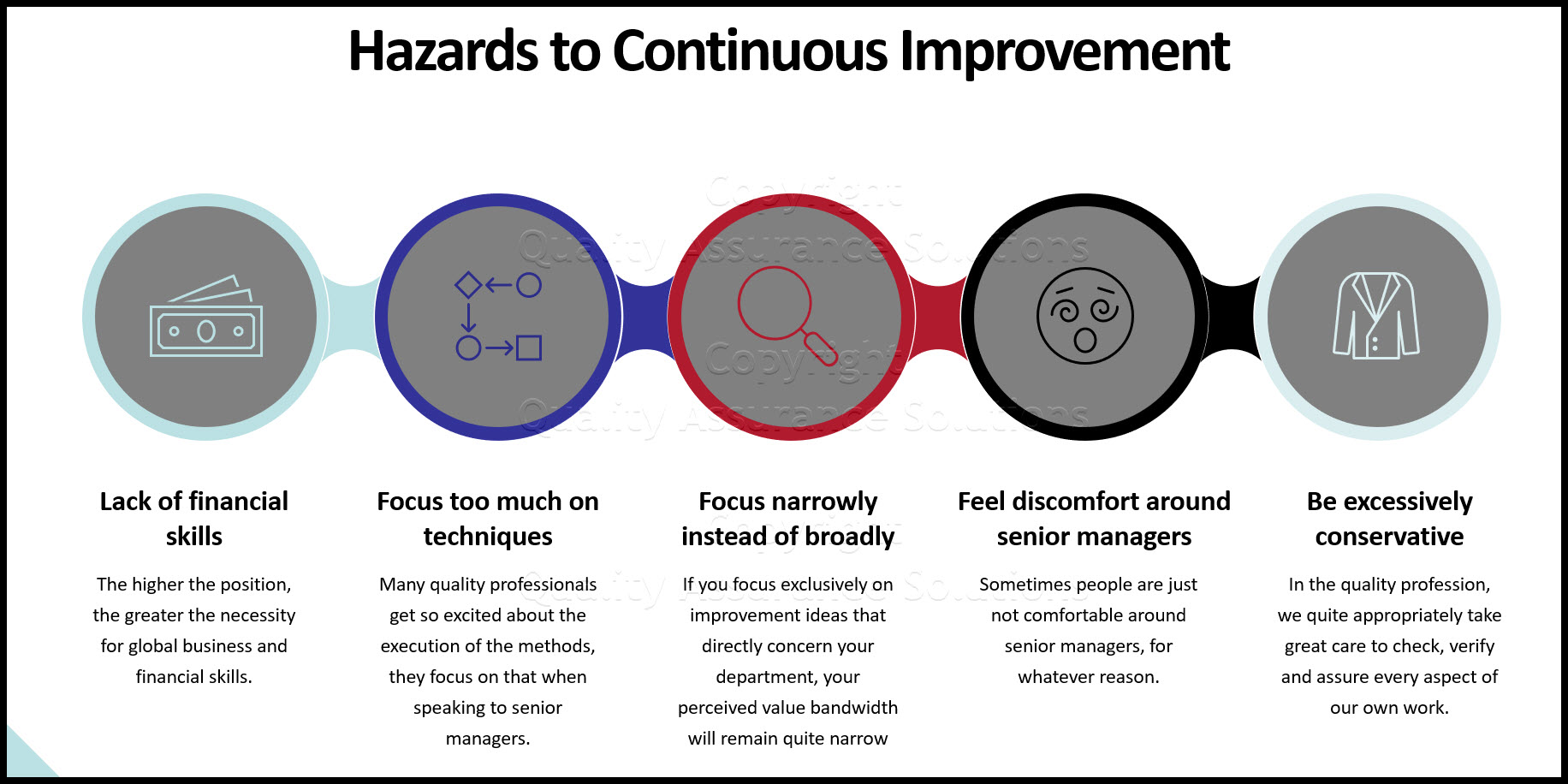

Whatever the acronym of the method eg TQM CQI or tool used eg FMEA or Six Sigma the important component of quality improvement is a dynamic process that often employs more than one quality improvement tool. Organizations have to invest time and money to satisfy funder and regulatory requirements for data collection. Continuous quality improvement CQI an approach used extensively in industrial and manufacturing sectors has been used in the health sector.

For more than 10 years now the demand for performance has become a major issue for the healthcare system. Assesses an organizations ability to meet customer requirements Align expectations between suppliers and customers Reduces waste variation and defects Increase customer satisfaction Welding Process Assessment System Special CQI-15. First used as a method for comparing production costs with those of competitors in the same sector benchmarking later became conceptualized and used as a method for continuous quality improvement CQI in any sector.

Another benefit is often uncovering new opportunities that present themselves when problems are identified and solutions are sought. Benefits of aligning your processes to the CQI-12 Coating System Assessment include. Fostering and sustaining a culture of change and safety developing and clarifying an.

It is highly recommended that the entire supply chain support the implementation of CQI-14 for the full benefit and improved performance to be realized. The Manufacturer suggests 74 of manufacturers accept that they need to adopt digital technologies in order to prosper but with the manufacturing industry hit hard by the current economic climate the pace of change needs to be stepped up. Increased productivity and employee job satisfaction are two more benefits.

These four CQI strategies are widely used in the health care industry today. Improving process makes wasteful activities associated with equipment supplies ideas and energy more obvious and makes it easier to eliminate. Primary Models for CQI in Healthcare A number of established models can help organizations perform effective continuous quality improvement.

Quality improvement requires five essential elements for success. Reinforce manufacturing process updates typically implemented as a result of a corrective action. The benefits of quality improvement usually reach far beyond a companys bottom line.

Manufacturing 528 36 73 Trade transportation and utilities 1008 42 43 Information 57 -01 -17 Financial activities 355 -01 -03 Professional and business services 694 19 28 Education and health services 925 12 13 Leisure and hospitality 520 107 259 Other services 243 22 100 Government 834 -28 -32. Meaningful Use is an important means to achieving the triple aims of health careimproving the experience of patient care improving population health and reducing per. Many of those models originated and are still used in other industries.

The Institute for Healthcare Improvement IHI Model for Improvement. The benefits of CQI include the following. But they can apply to healthcare organizations.

Reliable and streamlined processes are less expensive to maintain. Investment made to improve quality also has enormous benefit to the countries where the local manufacturing companies are located because of substantial foreign exchange savings and job creation. Systematically studying and using data makes good business sense and provides important information on which to base service.

This topic explains some of the. Most quality improvement methods are based on the application of continuous quality improvement theory developed by the manufacturing industry. The Importance of Quality in Manufacturingand the Inherent Disconnect Most if not all manufacturers will tell you their top priority is to improve quality.

Veeva is headquartered in the San Francisco Bay Area with offices throughout North America Europe Asia and Latin America. As a Public Benefit Corporation Veeva is committed to balancing the interests of all stakeholders including customers employees shareholders and the industries it serves. Conclusion This sort of deep culture change can be challenging but the ultimate return is far greater than any isolated improvement project.

A continuous improvement plan is a set of activities designed to bring gradual ongoing improvement to products services or processes through constant review measurement and action. It avoids the cost associated with process failure poor outcomes and errors. CQI models include the following.

Many well-established continuous quality improvement CQI programs and strategies exist to help your organization improve efficiency health care quality and patient outcomes. More competitive products services Continuous improvement drives both the improvement of processes and products. End customers demand quality products and in turn OEMs demand quality performance all.

Research published in the 2019 Annual Manufacturing Report from industry journal. Team member accountability Creativity and solution creation Heightened team member morale Improved processes information management and documentation Greater adaptability to changes Tools and methods to monitor program effectiveness Opportunities for additional programs and new program modules.

The Essential Guide To Continuous Quality Improvement Sweetprocess

Common Questions About Continuous Quality Improvement Cqi

The History Major Models Of Cqi Its Benefits In Healthcare It Industry Covetus Technologies Pvt Ltd

9 Brilliantly Simple Continuous Quality Improvement Techniques

Continuous Quality Improvement

The Essential Guide To Continuous Quality Improvement Sweetprocess

Need Help Meeting Or Understanding The New Cqi 9 4th Edition In 2021 Understanding Edition Helpful

Tools And Strategies For Continuous Quality Improvement And Patient Safety Nurse Key

0 Response to "BENEFIT OF CQI MANUFACTURING INDUSTRIES"

Post a Comment